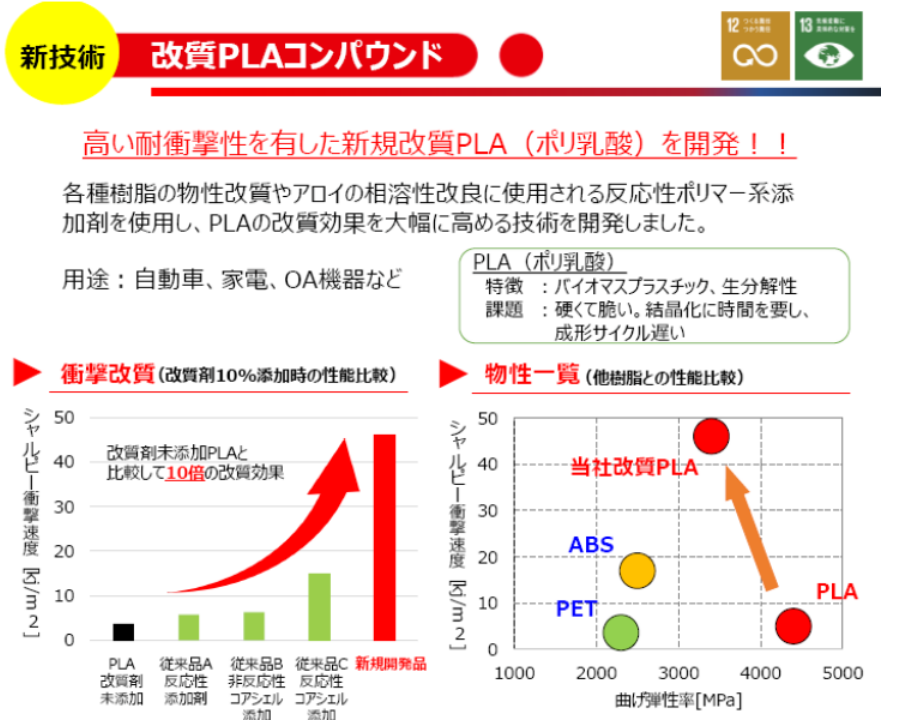

Recently, Sumika Color, a subsidiary of Sumitomo Chemical Group, has successfully significantly improved the resistance of polylactic acid (PLA) through the use of modifiers and the mixing technology of masterbatch (MB) and compounds. Shocking.

Compared with PLA without modifier, the Charpy Impact strength of PLA with 10% modifier added

Strength) increased nearly 10 times, and has good forming time (60~80 seconds). It is expected to be suitable for use in molded parts for automobiles, home appliances, office automation equipment, etc.

PLA, a biomass plastic derived from plants, is hard and brittle, takes time to crystallize, has a long molding cycle, and has poor productivity. Sumika

Color improves the impact resistance of PLA by utilizing reactive additives to cause an esterification reaction. After measuring the physical properties according to ASTM standards, the impact strength of PLA without modifier is 5

kJ/m2, the sample containing 10% modifier is 46.1 Kj, an increase of nearly 10 times.

In addition, in the drop weight impact test, a weight of 2 kg was dropped from a height of 80cm to a thickness of 2

mm modified PLA and inspected the damage state to confirm that no dents or damage were formed. In addition, the molding cycle of PLA has also been improved. Sumika

Color has shortened molding time by selecting the optimal nucleating agent, and has confirmed that molded products can be taken out within 60 to 80 seconds.

微信扫一扫打赏

微信扫一扫打赏