Terephthaloyl chloride is an ancient compound that was synthesized as early as the beginning of the 20th century. It has only been developed and utilized on a large scale in the past 20 to 30 years. In recent years, terephthaloyl chloride has become an important intermediate raw material and is widely used in the synthesis of artificial fibers and pesticides]. At present, the annual output of the herbicide dichlorsol, which is synthesized using terephthaloyl chloride as raw material, in the United States and Japan is around 1,000 tons. Poly-p-phenylene terephthalamide fiber, which is synthesized by the condensation of terephthaloyl chloride and p-phenylenediamine, has excellent properties such as high strength and high modulus. It is a type of man-made fiber with a wide range of uses and has attracted attention in various aspects. of attention.

Terephthaloyl chloride (TPC) is a light yellow needle-shaped substance that can be quickly hydrolyzed by moisture in the air to generate the corresponding acid. The purity of terephthaloyl chloride directly affects the performance of the products synthesized from it. At present, the production of terephthaloyl chloride mainly uses terephthalic acid as raw material. According to the different chlorinating agents used, it can be divided into phosgene method, ester chlorination method, etc.

1 Phosgene method

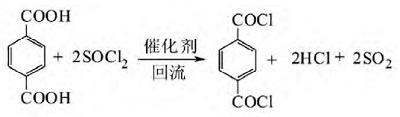

David et al. used terephthalic acid to pass phosgene in the presence of the catalyst DMF and the solvent chlorobenzene, and reacted at 90~100°C to generate terephthaloyl chloride. The melting point of the product is 80.4°C, and the yield is 84.0%. The reaction process is as follows:

Reactive 2

The above method was applied to industrial production by Japan’s Mitsui Toa Chemical Company in the 1970s. Domestic Chenguang Chemical Research Institute and Shenyang Resin Factory have also used this method to produce terephthaloyl chloride. This method specifically produces phosgene, which is a highly toxic gas, and great attention must be paid to operational safety and protection. The yield and quality of acid chloride are not as good as those of the acid chlorination method.

2 Ester chlorination method

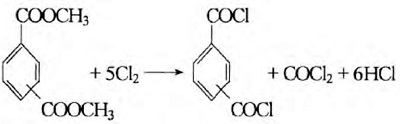

Use dimethyl terephthalate as the raw material, anisole or chlorobenzene as the solvent, pass in chlorine gas and react with the ester to synthesize acid chloride, the reaction process is as follows:

Reactive 3

Since no catalyst is used, the reaction temperature is generally above 180°C, and some use ultraviolet irradiation for the reaction. Xue Dejun and others improved the above preparation method. The improved method does not use solvents, but adds dimethyl terephthalate and a few grams of ceramic tiles into a reactor equipped with a reflux condensation device, heats the dimethyl terephthalate until it melts, and uses 200~300W incandescent tungsten The lamp is used as the light source, and chlorine gas is introduced at 150~250°C to carry out the reaction, and the crude yield is greatly improved.

When ester is used as raw material to prepare terephthalic acid chloride, impurities that cannot be removed when acid is used as raw material can be removed by vacuum distillation of the ester, and the acid chloride produced is of high quality and purity. However, dimethyl terephthalate is required as raw material, so methanol is consumed in the process of making methyl ester, and the reaction temperature is relatively high. This method was adopted in West Germany, the Soviet Union, and the United States.

Application prospects

Terephthaloyl chloride is mainly used to polymerize with p-phenylenediamine to produce high-performance fiber aramid 1414 (PPTA) and aramid sulfone (PSA). It is also used to produce plastic additives, polymer materials, and permeable membrane materials. With ���Pharmaceuticals and pesticides, etc. Among them, the development of high-performance aramid fibers is a key area for the development of this product. Focusing on strategic emerging industries, major national economic construction projects, national defense and military industry, and the upgrading and adjustment of the materials industry structure, terephthaloyl chloride will have good market prospects in my country.

微信扫一扫打赏

微信扫一扫打赏