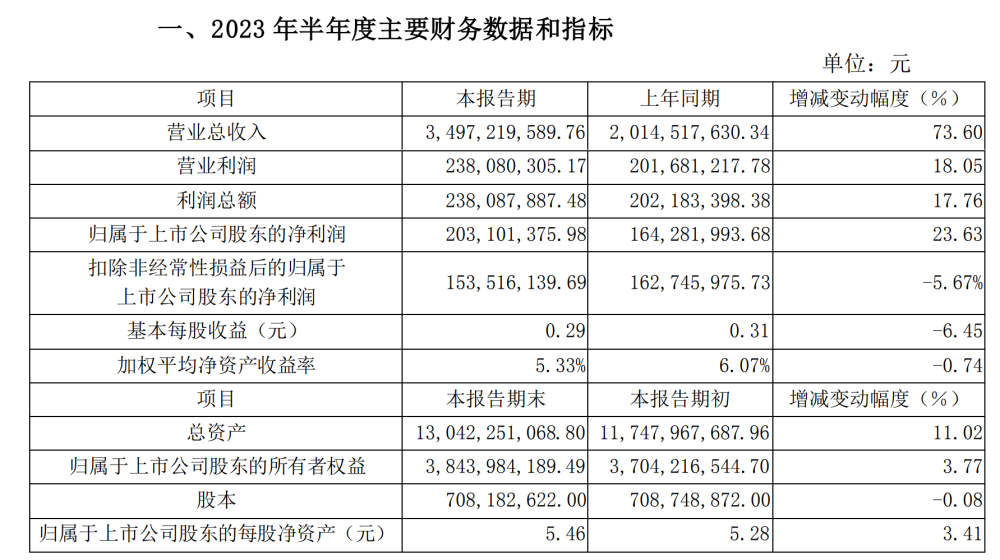

Recently, Donghua Technology announced its interim report. In the first half of 2023, it achieved operating income of 3.497 billion yuan, a year-on-year increase of 73.60%; net profit attributable to the parent company was 203 million yuan, a year-on-year increase of 23.63%, and its operating performance increased steadily. , the development quality is comprehensively improved.

The main reasons for the year-on-year increase in operating income are: first, the operating income base in the same period last year was small; second, during the reporting period, the company steadily promoted production and operation work, the general contracting projects under construction progressed normally, and the income recognized based on the completion progress increased year-on-year.

Donghua Technology is a large state-controlled engineering company. Its business areas mainly include engineering businesses such as chemical industry, environmental governance and infrastructure, as well as industrial businesses such as environmental facility operations and high-end chemical production.

In the engineering business, the company has undertaken multiple projects for PBAT, PBS, PPC, PHA, PLA and BDO

and other degradable material general contracting, design, and consulting projects, initially forming a performance advantage in the entire industry chain of degradable materials. Including Shaanxi Coal Group Gansu Yumen degradable materials.

Among high-end chemicals, the company has deployed the production of degradable material products such as PBAT.

As a naturally degradable material, degradable plastic has a unique role in environmental protection and is considered an “effective solution to white pollution.” During the “14th Five-Year Plan” period, the company will lay out its PBAT, PLA, and PBS product portfolios horizontally, and vertically integrate the R&D, production, and sales of raw materials, masterbatch, modifications, and products, striving to become an enterprise with the longest chain of the degradable materials industry chain and governance A leading company in “white pollution”.

The Donghua Tianye 100,000 tons/year PBAT project invested and controlled by the company was successfully launched at the end of June 2022. In accordance with the requirements of engineering optimization and industrial improvement, Donghua Tianye has carried out a series of chain expansions for production equipment. A series of production line chain expansion method transformations have been completed, with a PBAT production capacity of 60,000 tons/year. The second series of production line PBT transformations will be completed in 2023. Completed in August, it has an annual PBT production capacity of 40,000 tons. At the same time, through partial modification, both series one and two production lines can be converted to produce PBS. By then, Donghua Tianye can flexibly adjust the production capacity of PBAT, PBT and PBS according to market demand, opening up a new situation for Donghua Tianye’s production operations and profit growth.

The company is vigorously expanding the degradable materials industry chain, is developing polylactic acid (PLA) production technology, and has conquered the production technology of PLA intermediate product lactide. The “Polylactic Acid Technology Development Project” has carried out multiple rounds of pilot tests to optimize process parameters and provide data support for the 50,000 tons/year process package.

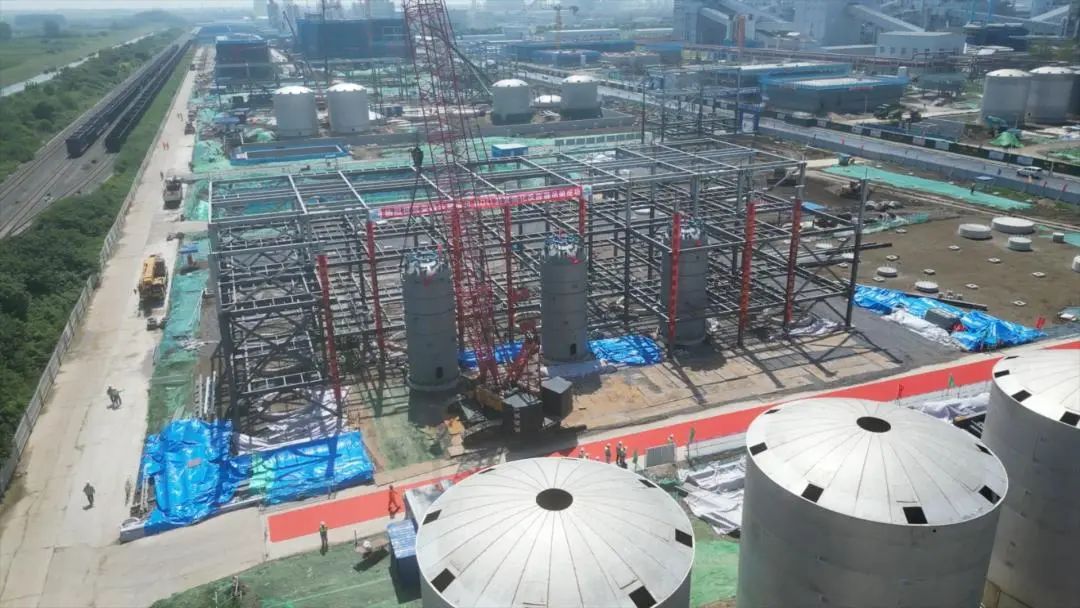

The Shuguang Luhua 100,000 tons/year BDO joint production and 120,000 tons PBAT project in which the company has invested and participated is under construction. On August 31, the first equipment of Huasu Co., Ltd.’s integrated product structure adjustment project with an annual output of 120,000 tons of biodegradable new materials, which was contracted by Donghua Technology, was successfully hoisted into place, marking the project entering the peak period of installation and construction. . The height of the alkynylation reactor is 10.685 meters, the maximum diameter is 4.58 meters, and the equipment weight is about 57.4 tons. This hoisting uses a 150-ton crawler crane as the main crane and a 75-ton truck crane as the tail crane.

微信扫一扫打赏

微信扫一扫打赏