On September 25, BASF announced that its integrated base in Ludwigshafen, Germany, has the production capacity to produce bio-based 2-octyl acrylate. It will promote the sustainable development of acrylic formulation systems in the fields of coatings and adhesives. This is also BASF’s latest progress in bio-based technology, following BASF’s bio-based butanediol (BDO) and bio-based plastic antioxidant products.

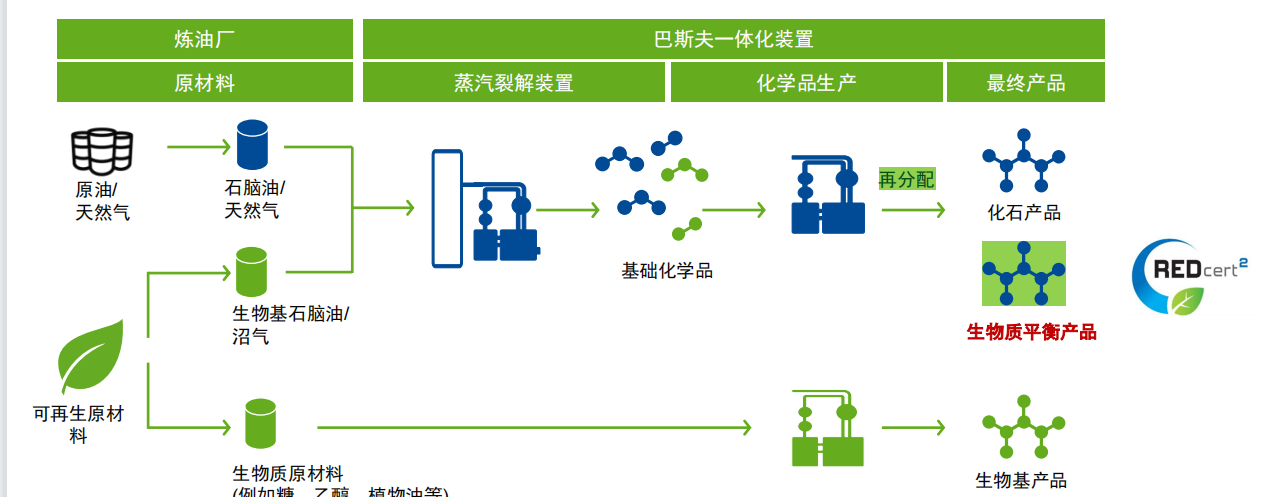

According to information disclosed by BASF, BASF is expanding its product range of carbon-14 bio-based monomer portfolio to produce 2-octyl acrylate (2-OA) through a proprietary process. According to ISO

16620, this new product demonstrates BASF’s strong commitment to innovating for a sustainable future and contains 73% traceable carbon-14 biobased content. In addition to its regular carbon-14 biobased 2-octyl acrylate, BASF also launches a new product, 2-octyl acrylate BMB

ISCC Plus. In this case, the remaining carbon content passes through the ISCC

PLUS certified, and by applying BASF’s Biomass Balance (BMB1) method, this variant offers a further reduced product carbon footprint (PCF2).

BASF operates an industrial-scale 2-octyl acrylate production facility at its integrated site in Ludwigshafen, Germany. This enables BASF to offer this bio-based monomer as a raw material globally. Reiner, Senior Vice President Industrial & Petrochemicals Europe, BASF

“We have expanded our product portfolio to support our customers on their sustainability journeys,” said Dr. Geier. “With 2-OA, we are proud to introduce a new acrylate monomer to help customers achieve their sustainability goals.”

BASF’s 2-octyl acrylate uses 2-octanol as the corresponding bio-based raw material. This bioalcohol is based on castor oil, a sustainable non-edible ingredient that is reliably available year-round. Due to its solubility balance, 2-octyl acrylate can be easily used as a bio-based alternative in areas such as chemical bonding agent formulations or coating applications, replacing fossil-based monomers such as isooctyl acrylate (2-EHA) and n-butyl acrylate. Esters (BA).

The new product also offers performance advantages over fossil fuel alternatives, with better wash resistance in coatings, better shear resistance and excellent weather resistance in adhesives. As a result, 2-octyl acrylate is one of the few carbon-14 biobased monomers available for standard and high-performance applications. BASF’s high purity, reliable quality and low volatile organic compound (VOC) content of propylene 2-octanoate enable customers to use the monomer in a wide range of applications.

BASF’s 2-octyl acrylate is registered in the European Union, the United States, Japan and many other countries. Further registrations are in progress.

Earlier, BASF in the United States, together with Qore® LLC (Cargill and HELM

AG’s joint venture) reached a cooperation agreement to obtain the long-term use rights of QIRA® bio-based 1,4-butanediol (BDO). At the same time, Qore will expand production of this bio-based BDO product at the biopark in Cargill, USA, and the corn refinery plant in Iowa to meet BASF’s production capacity needs.

In the bio-based scientific research on plastic additives, BASF announced the launch of a biomass-balanced plastic additive product portfolio that replaces fossil raw materials with renewable raw materials. First products include Irganox® 1010 BMBcert™

and Irganox® 1076 FD BMBcert™ antioxidant. The above products have passed ISCC PLUS mass balance certification by TüV Nord

Certification will promote sustainable development in the plastics field.

According to the sustainability reports released by BASF in recent years, BASF’s biomass balance program began to be implemented three years ago, when BASF purchased 120

Ten thousand tons of renewable raw materials, creating a biomass balance solution to save fossil resources, launching more than 240 biomass balance (BMB) products, accelerating the reduction of greenhouse gas emissions, among which, through REDcert-EU

Certified methanol meets the Renewable Energy Directive (RED) standards for high-quality biofuels.

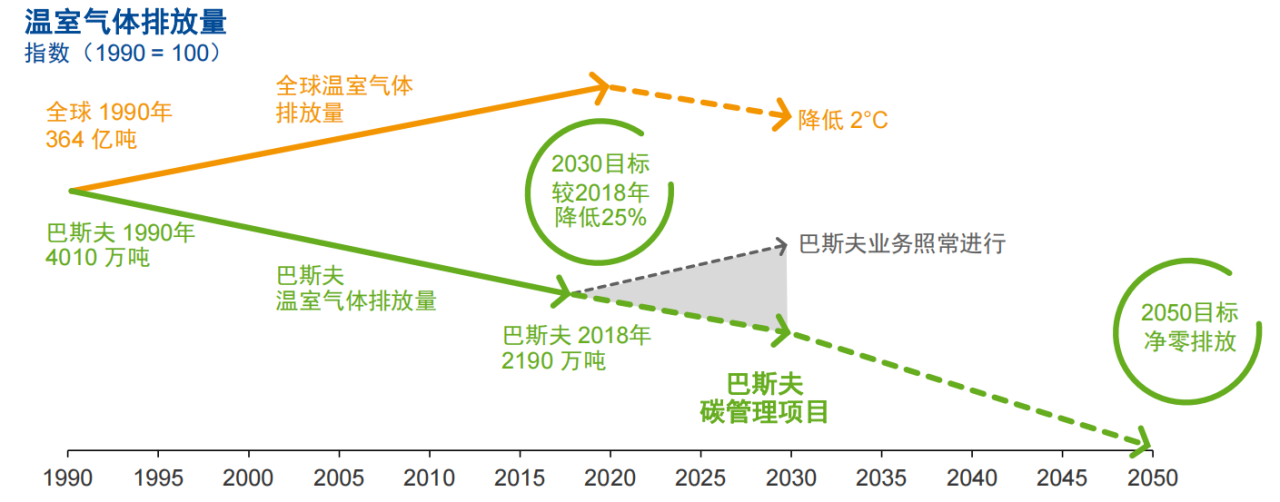

The reasons behind BASF’s deployment of these products are closely related to BASF’s goal of reducing carbon dioxide emissions. On the road to carbon neutrality, BASF has set itself the ambitious goal of achieving net-zero emissions by 2050.

BASF’s chemical product performance and 2030 and 2050 goal plans:

BASF continues to optimize processes, gradually replace fossil fuels with renewable energy, and develop new low-emission technologies to further reduce its overall carbon footprint. BASF plans to invest 1 billion euros by 2025 to meet new climate targets, and a further 2 billion to 3 billion euros by 2030. In its pursuit of change, BASF strives to find inspiration in unexpected places. Following the logic and trajectory of successful companies, we will share these layout cases with our partners in the bio-based industry, and together we will realize BASF’s optimism in the biomass energy and materials industry economy.

微信扫一扫打赏

微信扫一扫打赏