Rheological additives play a vital role in various industrial coatings and are key additives for adjusting the viscosity and performance of coating formulations. Rheology additives are designed to provide coating viscosity stability, improve workability, and influence the flow characteristics of the coating to ensure that the coating reaches good storage and application conditions.

Waterborne polyurea rheology additives have been increasingly used in various coating systems due to their unique rheological properties and excellent compatibility.

Rheovis® UR 1120, a new water-based polyurea rheology additive launched by BASF, has many advantages compared with traditional rheology additives, such as high efficiency, stability, thixotropy and environmental protection.

Product Features

Rheovis® UR 1120 is a new water-based polyurea rheology additive. This product can be used in various water-based industrial systems and is widely used in acrylic, polyurethane, water-based epoxy and other coatings.

Product Information

Application examples

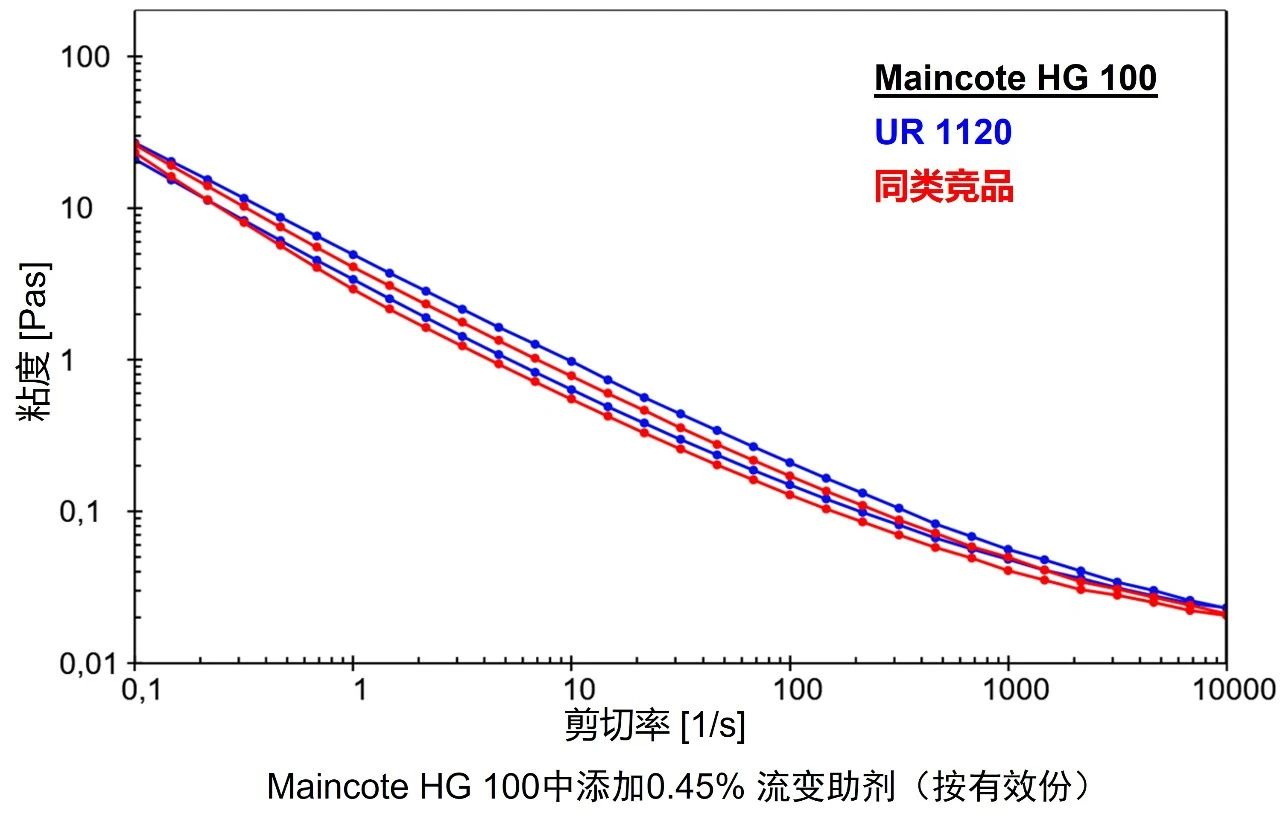

Rheology curve in emulsion

Rheovis® UR 1120

It can be seen from the emulsion rheology curve that Rheovis® UR 1120 exhibits slightly better viscosity thickening and recovery efficiency in a variety of emulsions than similar competing products on the market.

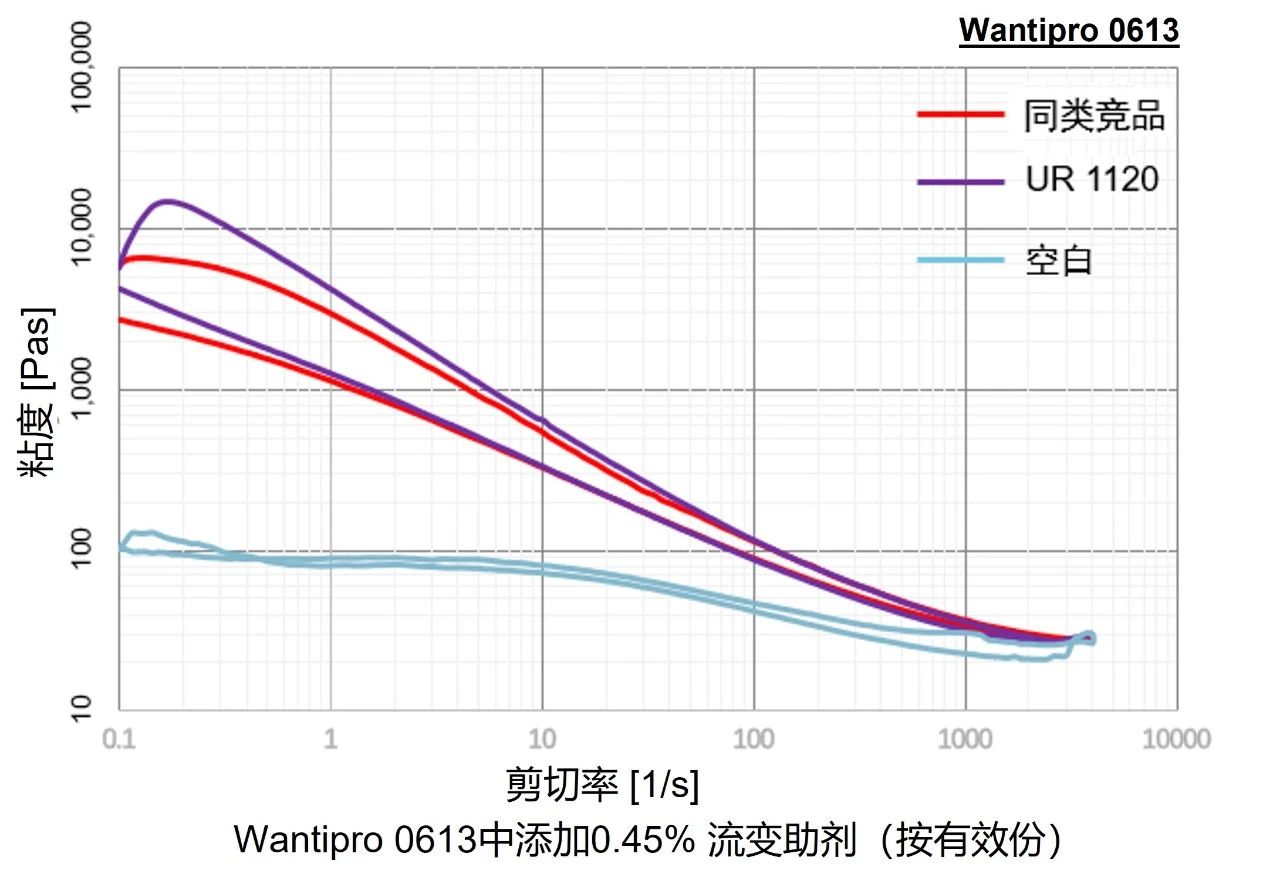

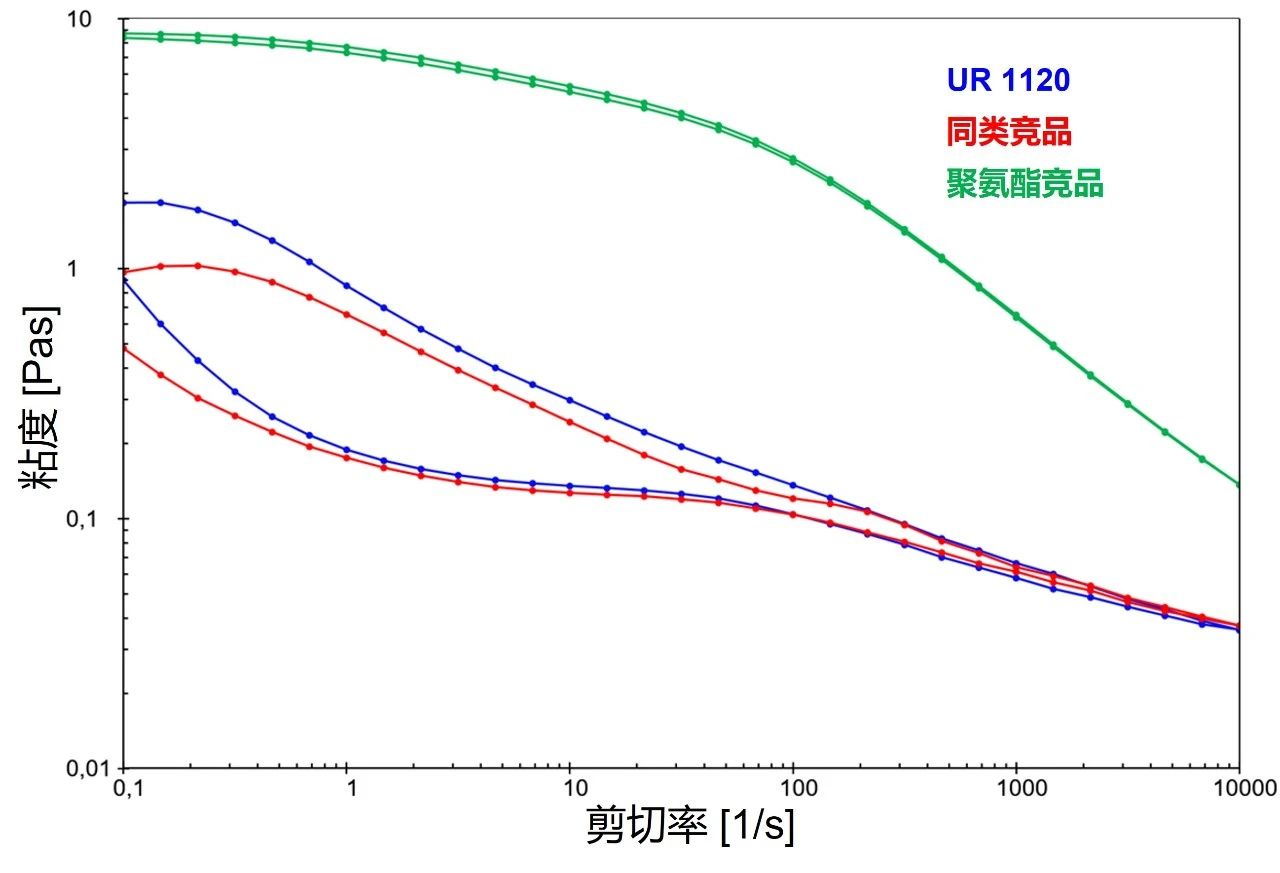

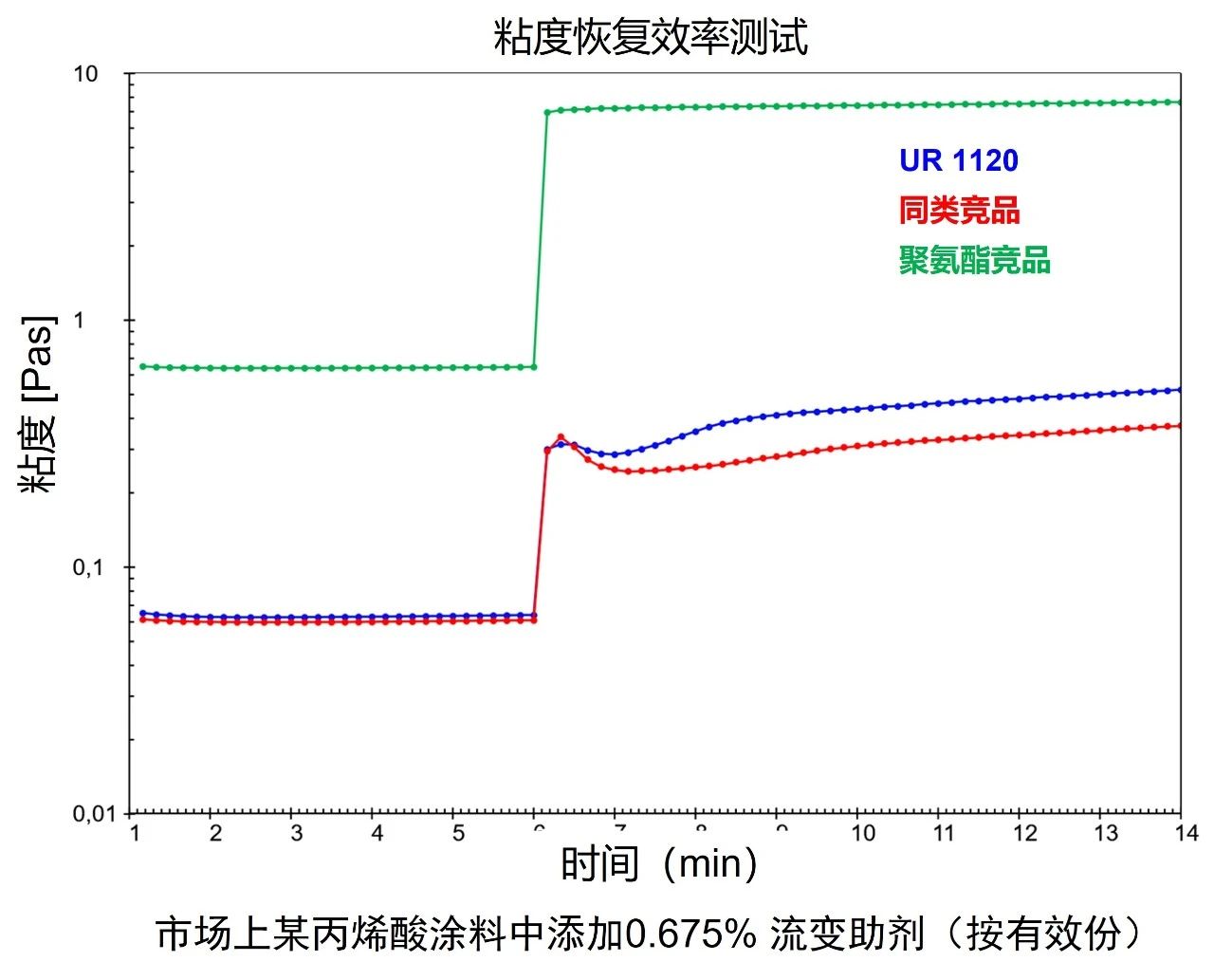

Rheology curves in coatings

Rheovis® UR 1120

As can be seen from the coating rheology curve above, the viscosity thickening efficiency of Rheovis® UR 1120 is slightly higher than that of similar competing products, and the viscosity recovery efficiency is equivalent to similar competing products.

Competing polyurethane products have different rheological properties from polyurea products, and their viscosity recovery speed is too fast, and their thixotropy is significantly lower than Rheovis® UR 1120 and similar competing products.

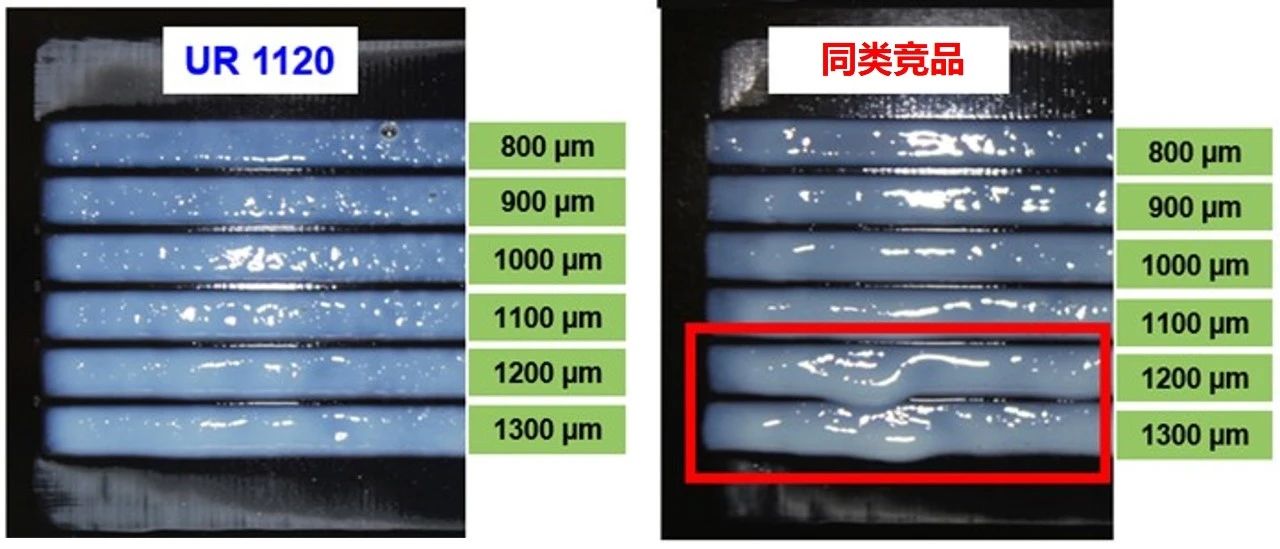

Anti-sag performance

Rheovis® UR 1120

In the thick coating construction process conditions, the anti-sag performance of the coating is a very important indicator. Add 0.45% rheology additive (based on effective part) to Maincote HG 100 to test its anti-sag performance.

As can be seen from the figure above, in the anti-sag test, Rheovis® UR 1120 has a significant advantage in anti-sag compared to similar competing products.

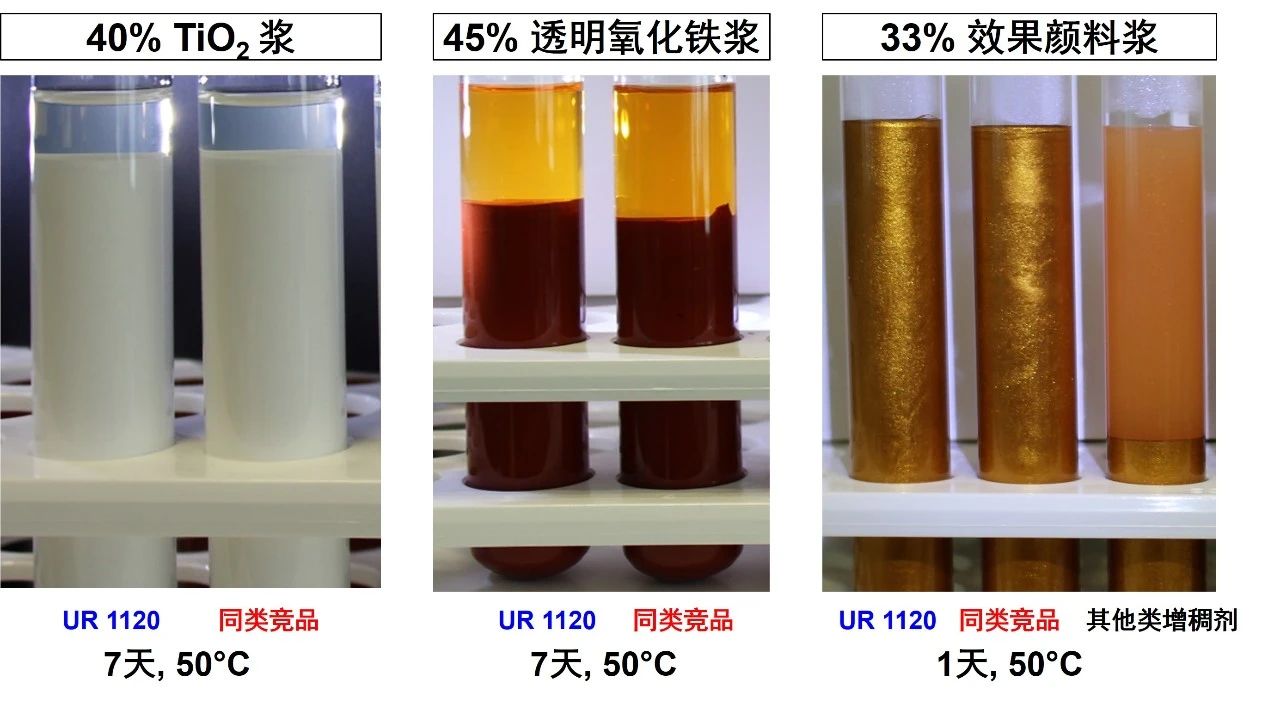

Anti-settling properties

Rheovis® UR 1120

Water separation between slurry and paint will inevitably occur during long-term storage, which will have a great impact on the appearance and application construction of the paint. High-performance low-shear rheology additives can alleviate such problems.

The picture above shows the settlement of different slurries after adding Rheovis® UR 1120 and similar competing products after storage in an oven at 50°C. It can be seen that Rheovis® UR

1120 has better settling resistance than similar competing products.

Effect of coating gloss

Rheovis® UR 1120

As you can see from the picture above, Rheovis® UR 1120 does not affect the gloss of the coating.

Summary

In summary, Rheovis® UR

1120 is a highly efficient water-based polyurea rheology additive with many features such as simple addition, excellent anti-settling and anti-sag properties, excellent thixotropy, no impact on gloss, and water-based environmental protection. Choose Rheovis® UR

1120, so you no longer have to worry about the rheology of paint.

微信扫一扫打赏

微信扫一扫打赏