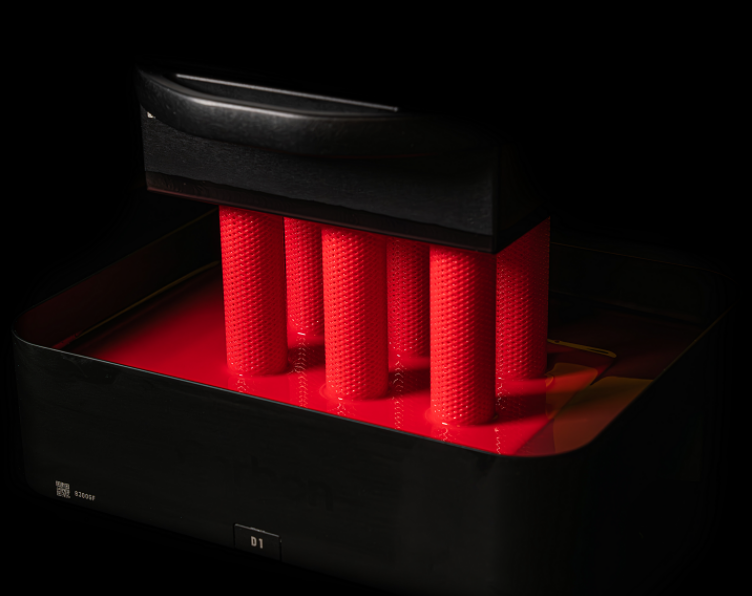

In 2015, venture-backed Carbon emerged as the first company to bring continuous digital light processing (DLP) to

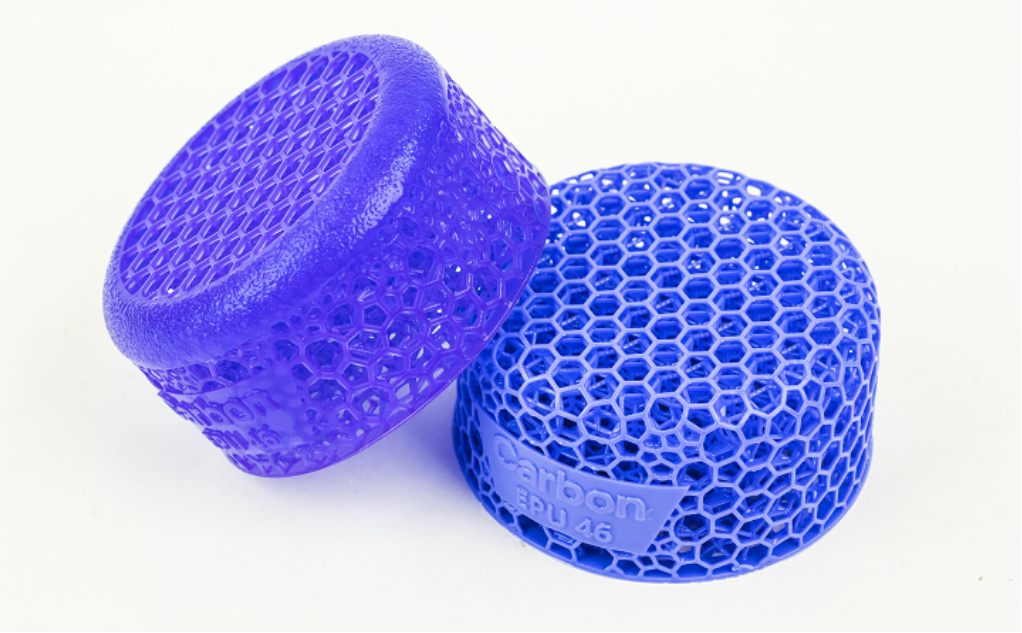

Technology commercialization company. The 3D printing unicorn has impressed the industry not only with the speed of its Continuous Liquid Interface Production (CLIP) solution, but also with its ability to print end-use parts using heat treatments and special chemical formulations. Carbon’s materials are used in a range of branded shoes and apparel, such as Adidas, CCM and Rawlings. As Carbon launches new high-performance polyurethane elastomer EPU

46, more similar applications may emerge.

Carbon already has a fairly robust materials library, which includes six other elastomer products: SIL 30, EPU 40, EPU 41, EPU 43, EPU 44 and EPU

45. By incorporating the new customizable EPU

With the addition of 46 to its product portfolio, Carbon can grow its platform from idea to production and meet growing demand for new product opportunities. Plus, it’s claimed to be a more sustainable material choice.

Jason Rolland, Senior Vice President of Carbon Materials Business said: “EPU

46 is the future of elastomer customization, combining the benefits of performance, comfort and durability with custom colors and adjustable material stiffness. EPU

46 furthers our commitment to deliver a powerful and complete idea-to-production platform that is fully customizable to our clients’ specifications. ”

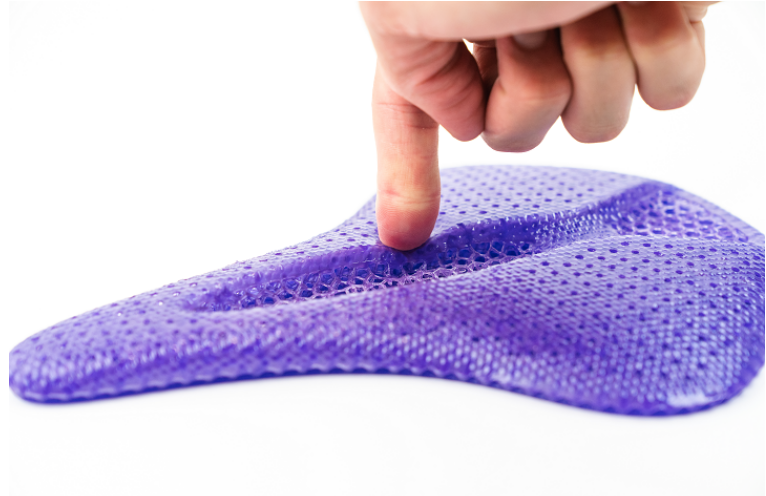

EPU stands for Elastic Polyurethane and has the properties of rubber, which is why it’s perfect for applications like midsoles. It is also comparable to thermoplastic polyurethane elastomer (TPU). Carbon’s family of elastomeric materials offer functional toughness, chemical resistance, abrasion resistance and UV resistance, and these materials offer high impact resistance, sterilization compatibility and energy buffering. Carbon’s new EPU

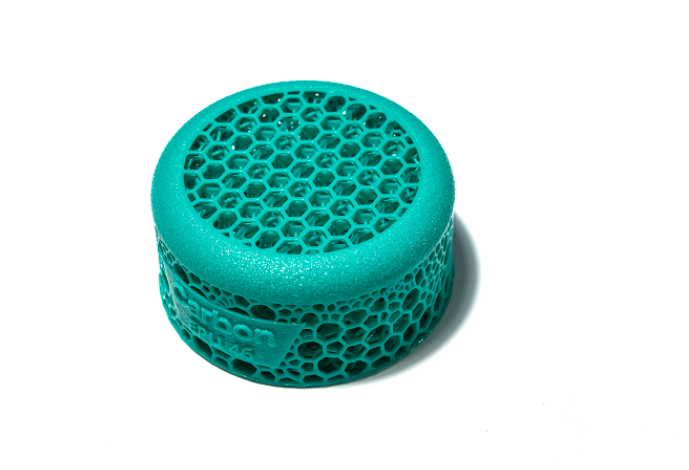

46 has a wide range of color options to enable customized products, designed to meet the needs of high-end products in terms of aesthetics, comfort and performance. The material has excellent durability and high-performance material properties, and users can also fine-tune its material stiffness without changing its properties or affecting printability.

The material’s excellent energy-return, dual-cure properties provide several important advantages, including speed and customization. EPU

46 offers fast print times, excellent printability, and a range of material hardnesses and colors. Speaking of these customizable colors, they won’t change or wear off because Carbon has added the pigments directly into the resin. It also has Shore

Adjustable material stiffness values from 78A-55A as the company is able to adjust lattice parameters such as cell size and strut diameter to allow for a wider range. This also enables applications requiring tactile qualities.

Carbon’s new EPU

Designed for high-volume production efficiency for demanding high-performance applications, the 46 should be an excellent choice for high-end products such as footwear, grips, and bike saddles due to its inherent customization capabilities.

What’s probably most exciting about Carbon’s new EPU46 is that it advances the company’s eco-friendly efforts. Carbon has identified four main sustainability focus areas to help minimize its impact on the planet: recycling, hazardous waste reduction, partial dematerialization and bio-based raw materials.

“Biologically derived raw materials from sources such as plants or microorganisms are renewable and have a much lower carbon footprint than petroleum-derived materials,” said Carbon. Carbon has partnered with DuPont Tate

&

Lyle and other companies are working together to use bioderived precursors as polyurethane components in resin formulations. Compared to petroleum-derived materials, these bio-derived materials produce 56% fewer greenhouse gas emissions and use 42% less non-renewable energy. ”

Like Carbon’s EPU44, this new elastomer contains 40% bio-based ingredients; its RPU

130 contains 25% (by weight) bio-based ingredients. Additionally, to reduce production waste, the EPU46 is designed for solvent-free spin cleaning and resin recovery.

Carbon’s new EPU 46 material will be available globally by the end of this month.

微信扫一扫打赏

微信扫一扫打赏